Introduction to FRP Pipes

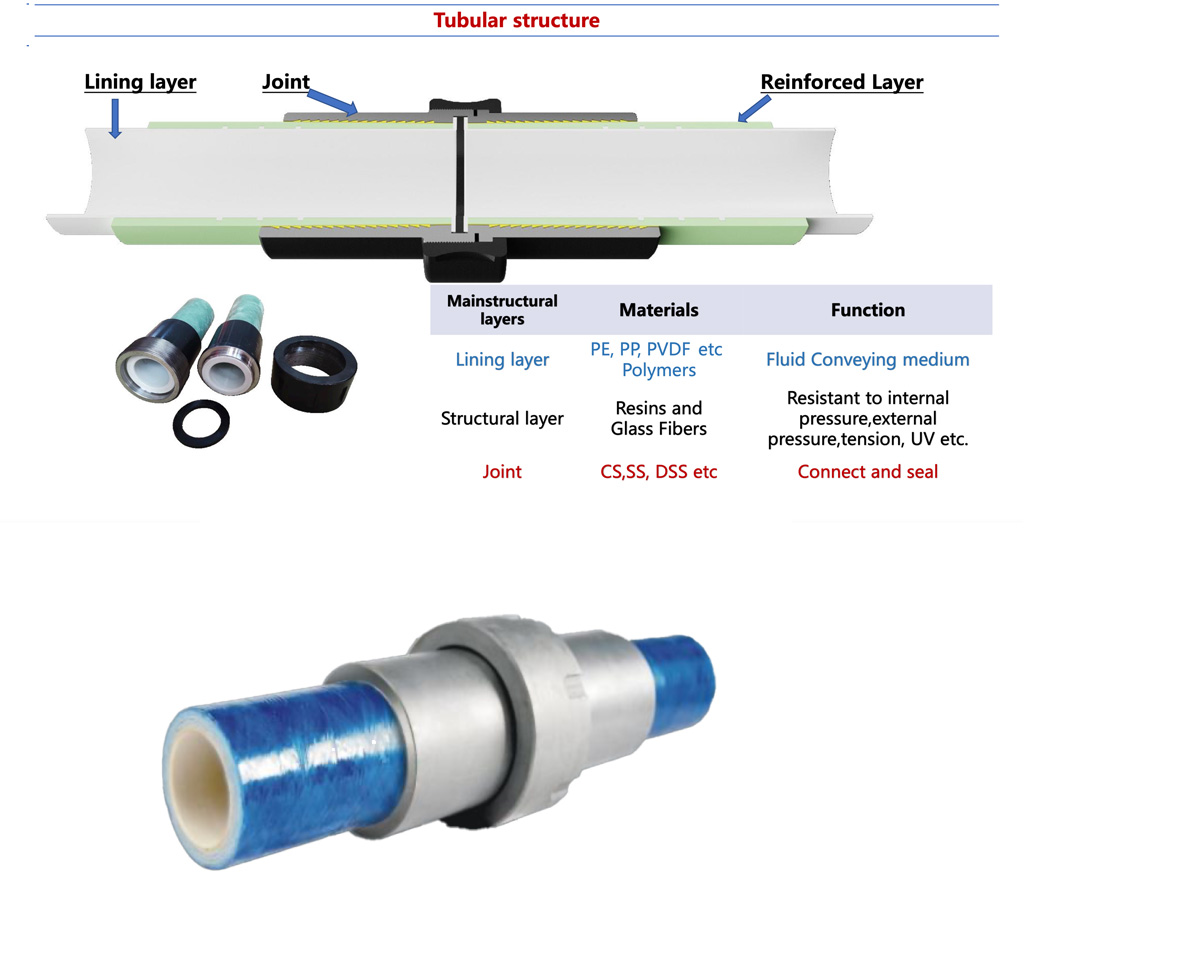

1. Structurecomposition

The pipeline is primarily composed of an inner layer, a reinforcement layer, and an outer layer (or protective layer):

- Inner Layer: The inner layer is usually made of high-density polyethylene (HDPEor other thermoplastic materials, offering good corrosion resistance, abrasion resistance, and sealing properties.

- Reinforcement Layer: Glass fibers or their products (such as fiberglass ropes, rovings, etc.) are used as reinforcement materials, which are combined with thermoplastic materials through specific processes (such as spiral winding) to form a high-strength, high-rigidity composite structure. This layer is the primary pressure-bearing part of the pipeline.

- Outer Layer (or Protective Layer): One or more protective layers can be added as needed to protect the reinforcement layer from external environmental corrosion, while also enhancing the overall strength and durability of the pipeline.

2. Performance Characteristics

- High Pressure-Bearing Capacity: Due to the presence of the reinforcement layer, the pipeline has a high pressure-bearing capacity, making it suitable for high-pressure transportation systems.

- Strong Corrosion Resistance: The inner layer uses thermoplastic materials, offering excellent corrosion resistance and the ability to withstand the erosion of various chemicals.

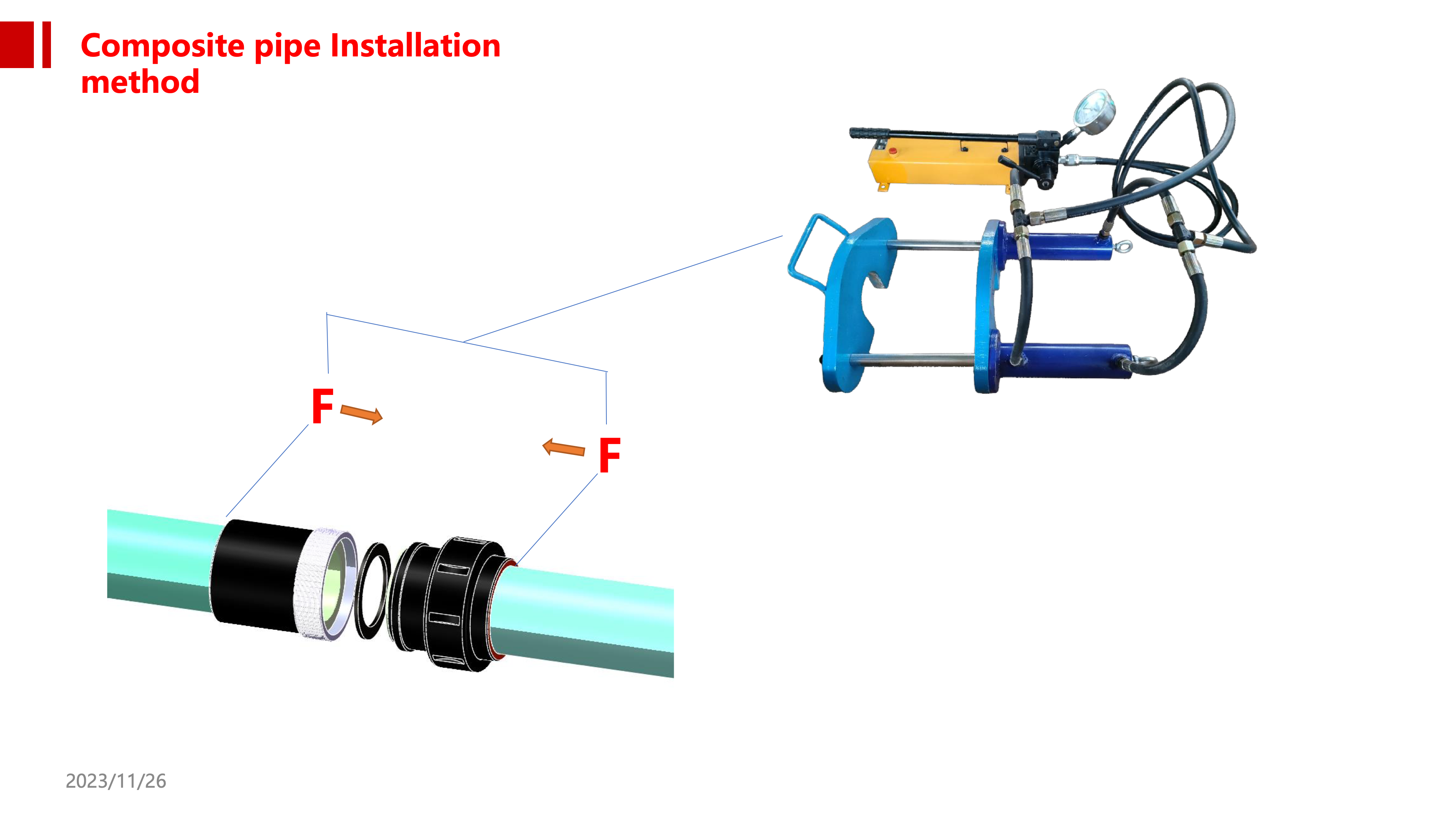

- Lightweight: Compared to traditional steel pipes, this pipeline is lighter in weight, making it easier to transport and install.

- Good Flexibility: The combination of thermoplastic plastic lining and fiberglass reinforcement materials gives the pipeline a certain level of flexibility, allowing it to adapt to complex terrains and installation requirements.

- Easy to Install: The pipeline can be coiled and is easy to connect, reducing the number of construction joints and improving both construction efficiency and reliability.

- Long Service Life: Under normal usage conditions, the pipeline can have a service life of several decades.

3. Application Fields

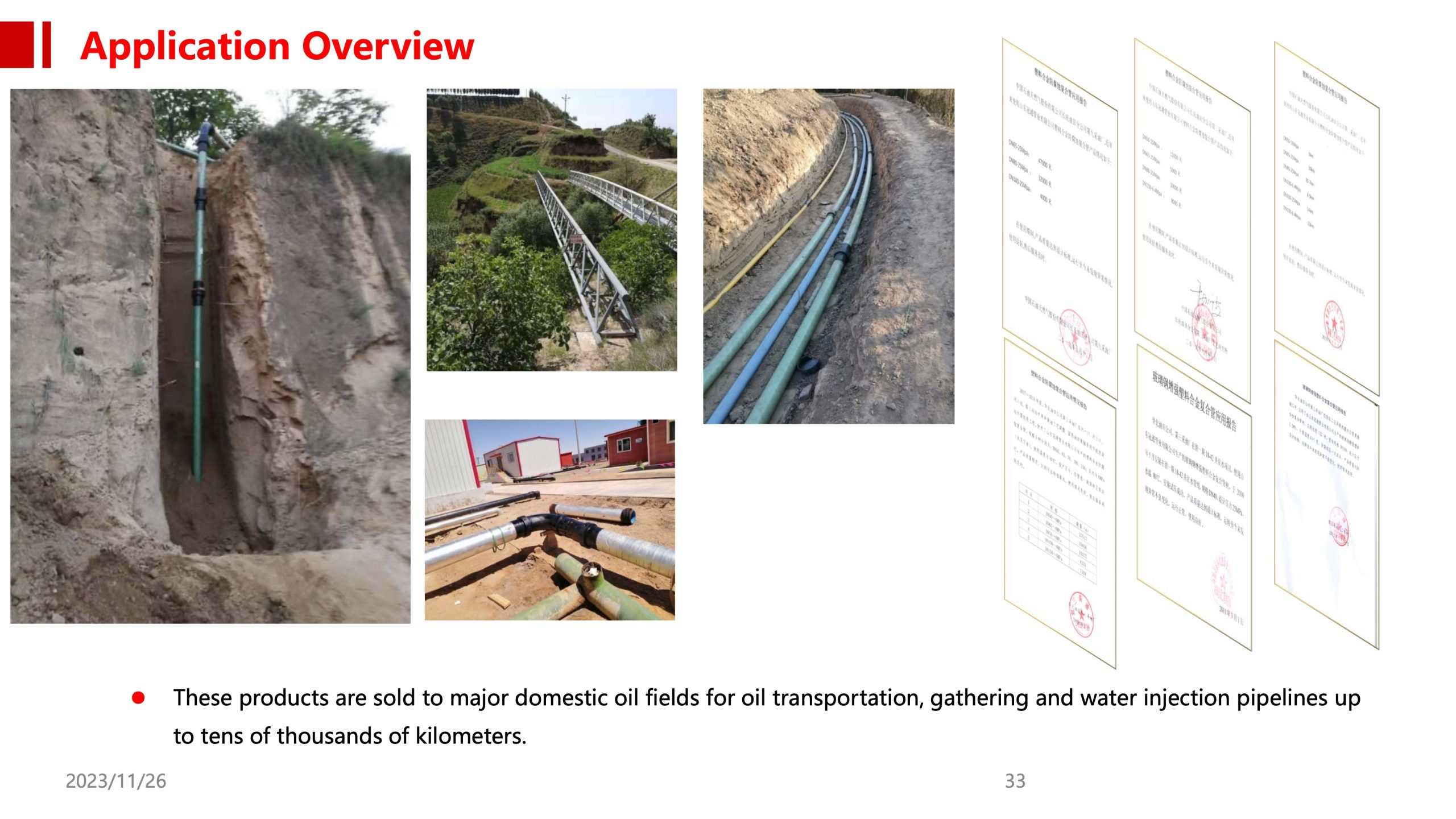

Thermoplastic plastic-lined fiberglass reinforced plastic composite pipes are widely used in various fields due to their excellent performance characteristics:

- Oil and Gas Extraction: Serving as oil pipes, water injection pipes, and high-pressure transportation pipelines, they meet the requirements for high pressure and corrosion resistance.

- Urban Pipeline Networks: Used in municipal pipeline systems for water supply, gas supply, etc., enhancing the safety and reliability of the pipeline system.

- Chemical Industry: Used as pipelines for transporting various chemical media, offering excellent corrosion resistance and pressure-bearing capacity.

- Mining and Industry: Used in hydraulic transmission system pipelines and other applications requiring high-strength, corrosion-resistant pipes.

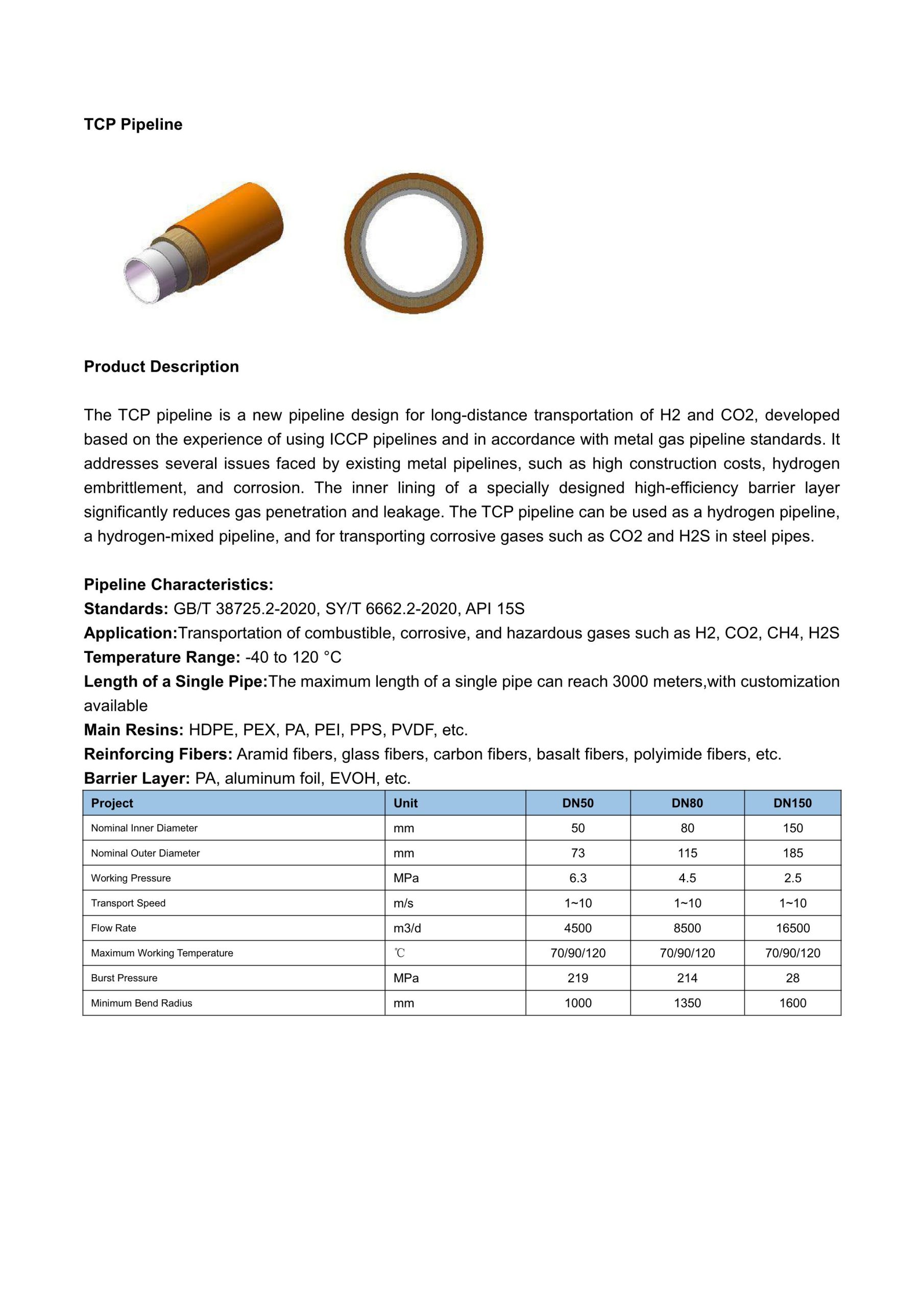

Introduction to TCP Pipes